An extremely durable material, but also with an elegant appearance, wood is used for building houses or interior finishing. For this reason, wooden staircases are a popular choice. Read our article and find out how to make a wooden staircase, and also about the different types and structures.

An extremely durable material, but also with an elegant appearance, wood is used for building houses or interior finishing. For this reason, wooden staircases are a popular choice. Read our article and find out how to make a wooden staircase, and also about the different types and structures.

Types of indoor wooden staircases

Which method will be best for making a wooden staircase in your home largely depends on the type of staircase you want. There is a very broad division, mostly based on the design. Therefore, let’s start off by having a look at what wooden staircases consist of:

- flights – the inclined part for walking up and down the stairs, which is made of steps,

- landings – at the top and bottom of every flight,

- quarter and half landings – steps that allows you to change the direction of the flight,

- the tread – the horizontal part of the step,

- the riser – the vertical part of the step,

- the string – the side beam of the flight.

Additionally, staircases can be equipped with railings to ensure stability when climbing or descending. Railings are composed of:

- handrails – serve as support when using the staircase,

- posts – mounted at the beginning, end and any changes of direction of the railing,

- balusters – elements located under the handrail. Glass panels are sometimes used instead.

Stringer staircases

The most common type of staircases are stringer stairs, which have side beams on both sides to support the entire structure. They usually have milled holes into which the treads and risers are inserted, and they are then screwed on with metal rods with threaded ends. You will also come across designs without risers, letting you enjoy openwork stairs. Railings are usually mounted to the stringers.

Saddled stairs

This type of stringer staircases are also called saddled stairs, and are distinguished by their saw-tooth stringers. The treads are then placed on them and screwed on from above. Risers can also be left out here. In the case of staircases with railings, the posts are attached directly to the steps.

String-saddled staircases

As the name suggests, this is a combination of the two types mentioned above. The traditional strings are then screwed on from the outside, i.e. next to the wall. Thanks to this, the saw-tooth stringer is exposed, which positively affects the design of the whole construction.

Cantilever staircases

This is another variation of string staircases. Here too, the string is mounted to the wall from the outside. This time, however, vertical thin posts are used instead of the inner banister. These are small wooden or metal posts placed between the treads. Together with the absence of risers, a modern, open design is achieved.

Floating staircases

With this type, the treads and risers are of the same length, and the strings are usually replaced by brackets. Alternatively, you could also use the railing to hold up the construction, letting you achieve a hanging effect. The name comes from the fact that the whole structure looks like it is floating. It is a great idea if your interior design focuses on symmetry and simple geometric shapes.

Single, double and triple-flight staircases

The number of flights in the staircase depends on how many landings have been used. Single flight staircases do not have any such elements, making them relatively easy to assemble, but more tiring to climb. Double and triple flight staircases have one and two landings, respectively. They let you change the direction of the staircase and enable a short rest while climbing.

Turning staircases

Spiral staircases are recommended in small houses and two-story apartments. They usually have a very compact design and the treads radiate around a central pole. Since the centre pole and landing typically provide the structural support for the stairs, they do not need much in the way of extra support structures, making installation easier than with many other types of stairs. Despite their effective design, they also have some disadvantages. It is difficult to carry large items up spiral stairs, and only one person can go up or down the stairs at the same time.

Winder stairs

An alternative for both double flight and turning staircases are winder stairs. Winder stairs are a variation of an L-shaped stair, but instead of a flat landing, they have pie-shaped or triangular steps at the corner transition.

Which type of wood should be used for making the steps?

Among the most popular questions regarding building a wooden staircase, the material that should be used is high on the list. A common opinion is that the best wood is from deciduous trees, commonly found in Europe. This means oak, maple, birch, ash, cherry or walnut. Beech is generally avoided because of its susceptibility to deformation. Exotic trees such as iroko, merbau, teak, jatoba and tatajuba are perfect for more luxurious and more expensive stairs. A cheaper solution is to use conifers, such as pine or spruce, but you should bear in mind that their wood is softer and less durable. It is better for structures that do not need to bear high loads.

Before choosing the wood for your stairs, check if it is of suitable quality, and if it has the right grain density. This shows the strength of the material. Also pay attention to the presence of knots and other imperfections that could affect the durability of the whole structure. Moisture is also important, and should be below 8-12%. In the case of the wood class, it is recommended to use class II wood for the steps and class I for the other elements.

In recent years, solid wood has been replaced by veneered elements, made of special wooden boards covered with natural veneer. Staircases made of such wood are more resistant to warping. However, bear in mind that they cannot be sanded, so if the surface is damaged, the veneer will need to be replaced with a new one.

At what stage of construction should a wooden staircase be made?

With wooden staircases, you don’t have to pay special attention to the different stages of building a house. In the case of reinforced concrete stairs, they should be carefully planned in advance and built early on. Wooden staircases can be fitted much later, e.g. when the house already has a roof, windows, or an active heating system. You can wait to lay the floor until the entire structure is finished. You only need to know where the stairs are to be built.

Advantages of wooden staircases

A definite advantage of wooden staircases is the appearance of wood, which creates a unique atmosphere. The material used is also very durable and can withstand heavy loads.

Wooden staircases are also less problematic than concrete stairs. As already mentioned, you can wait until the later stages of building the house before fitting a wooden staircase. Moreover, it is not permanently connected to the building, whichmeans that you can build a wooden staircase even in places where one was not planned.

There is also a wide range of assembly options. Many companies offer comprehensive services related to the production of entire structures and installing them at your home. You will also find modular kits for self-installation. However, if you are into DIY around the house, you could even go all the way and purchase the necessary materials from a carpenter and build a wooden staircase yourself.

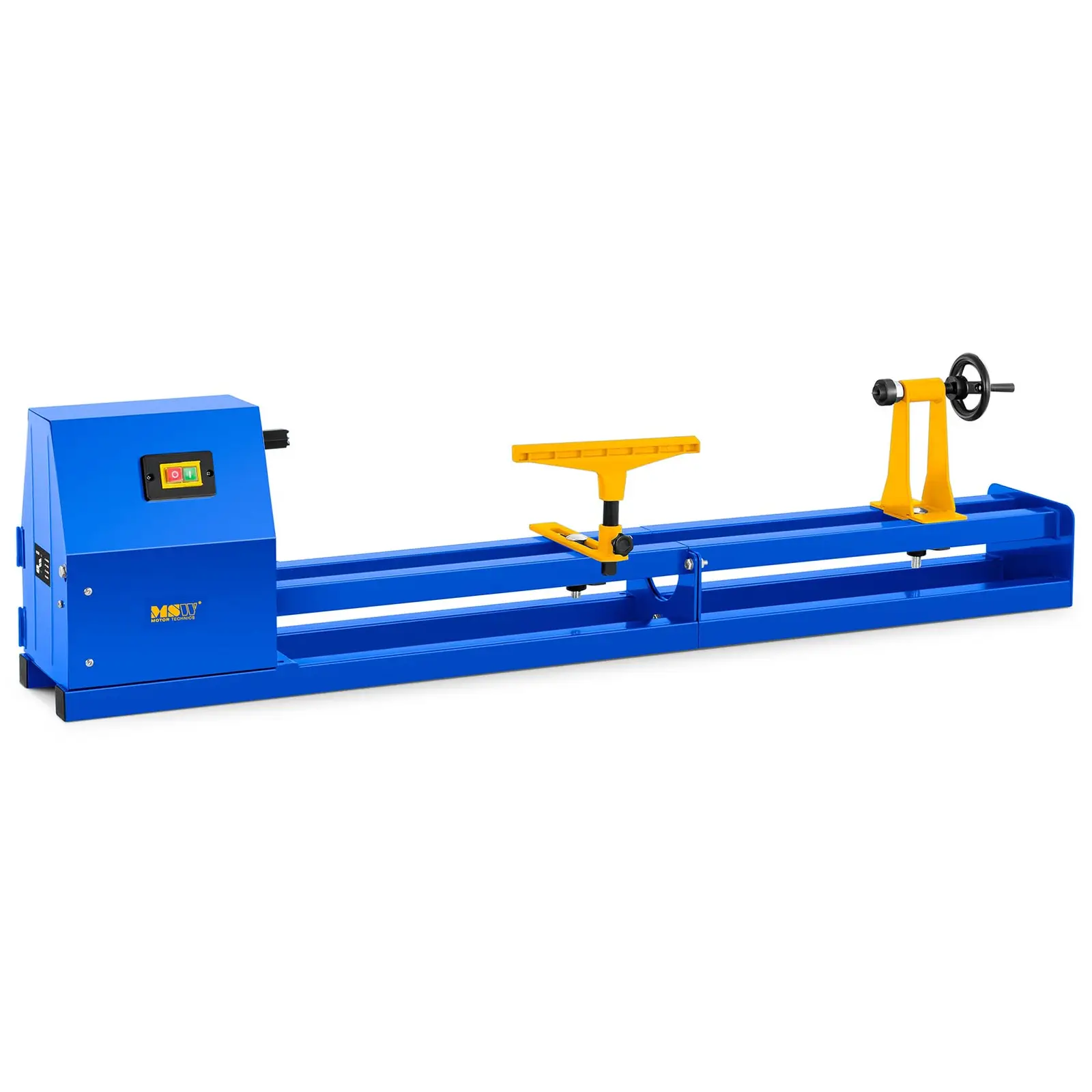

Necessary tools for the construction of wooden staircases

Due to the fact that you will mainly be working with wood, you will need appropriate machines and tools. These include multi-functional saws for cutting the boards and individual elements. Many of these devices have practical features, such as the possibility to saw at an angle, which will come in handy if you need irregularly shaped steps. You can use band saws, jigsaws, sabre saws and various types of circular wood saws.

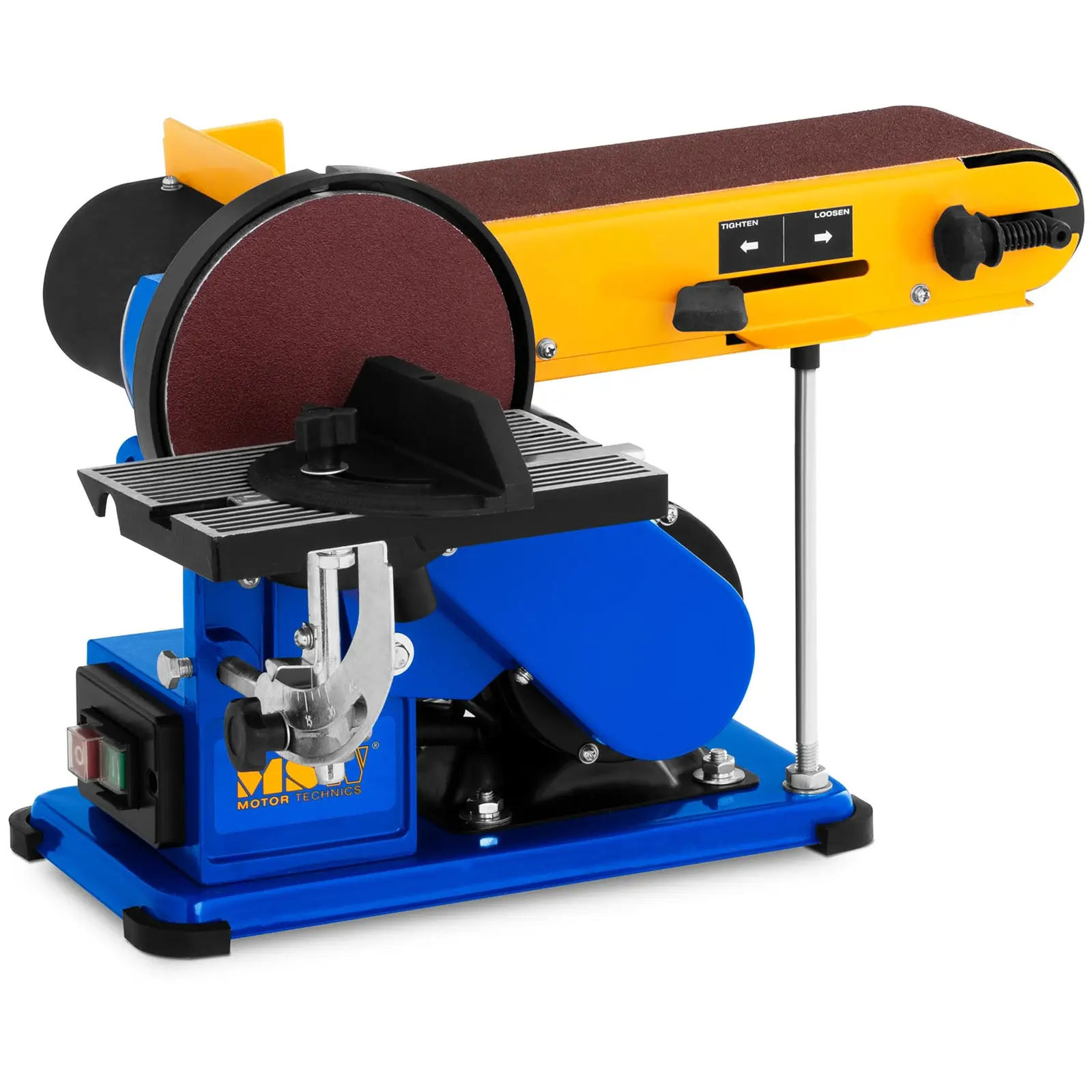

After cutting the boards, you will need to sand them properly in order to get rid of the rough surface, splinters and burrs that could risk injury when walking on the finished steps. For this you will need grinders and burnishing tools. Also, don’t forget to choose the right abrasive material, that is paper with a lower granularity to remove large imperfections before gradually moving on to a finer grain. This way you will achieve a perfectly smooth surface.

When processing wood always pay attention to health and safety rules, which includes wearing protective goggles and gloves. Thanks to this, you will avoid the risk of injury to your eyes and hands. When sanding, also wear a mask to prevent you from inhaling dust.

How to make a wooden staircase – summary

Wooden staircases are much more than just a way of getting from one floor to another – they are also a basic element of interior design. It is therefore important to choose the right style of staircase and the appropriate type of wood. You should now know how to make a wooden staircase that will meet your expectations.

If you want to discover some other construction secrets, read our other articles on related topics. Among others you will find out how to cheaply build a house.

Share